Coat-N-Cure Systems

The Perfect Way To Get Started In Powder Coating

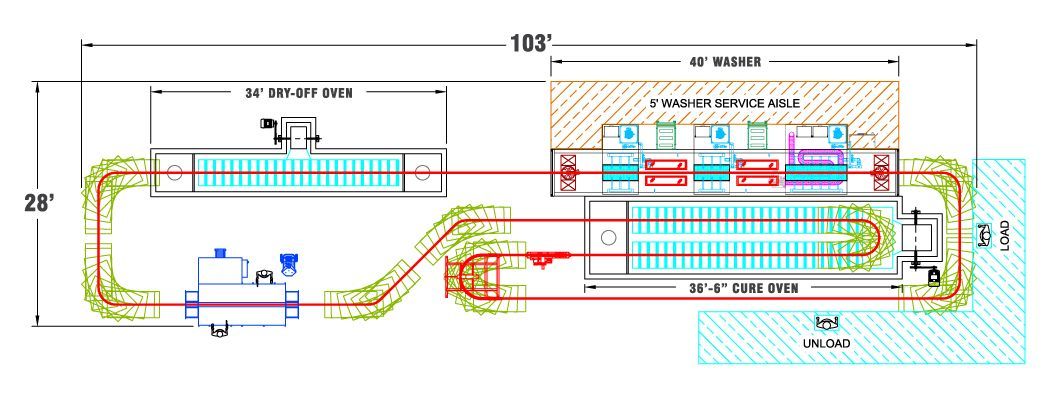

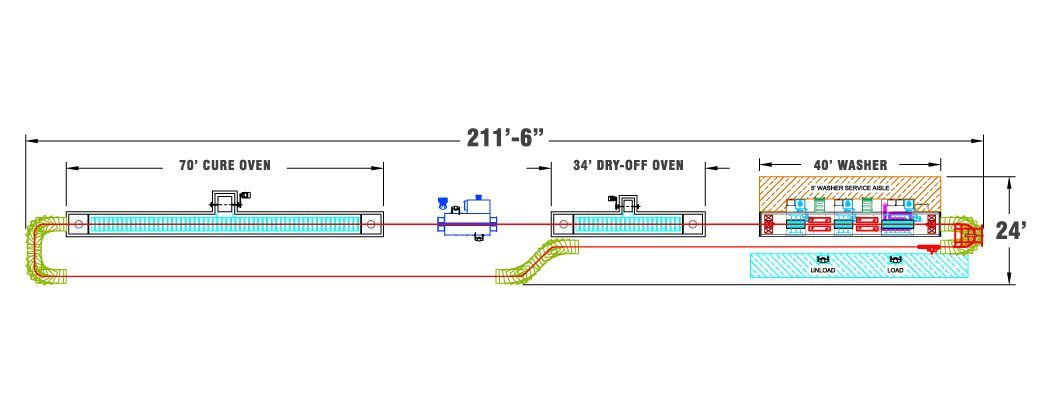

Coat-N-Cure. One name says it all. An entry-level powder coating system designed with a manual powder application booth (supplied by third party) and a cure oven so that users can establish themselves in powder coating quickly and cost-effectively. The Coat-N-Cure systems can easily be expanded by adding a washer and dry-off oven. These systems are pre-engineered, pre-wired, and ready to ship. Your powder coating line can be up and running in one week after the delivery of equipment.

Coat-N-Cure Features

The standard Coat-N-Cure system can process parts up to 6 feet in length, while our straight-through design accommodates parts up to 10 feet and more. Components are custom designed and configured to your plant layout. Our modular powder coating system comes with an energy-efficient gas convection cure oven with 6" insulated walls and conveyor system. It's delivered to your facility on our own trucks and is installed using only trained and experienced Midwest Finishing employees.

- Great entry-level system for powder coating parts

- Coat non-reclaim colors with Coat-N-Cure while running reclaim colors on your primary system

- Good for coating pre-treated or shot blasted parts

- Powder topcoat over E-coated parts

- Use as individual finishing "cells" throughout larger manufacturing facilities

While Coat-N-Cure is an excellent choice for a powder coating line, it may also be used to supplement larger systems when small run color changes are required or they may be used as individual "lean cells" throughout the plant.

READY TO START YOUR PROJECT?

Engineering the Industry's Most Energy Efficient Powder Coating Systems Since 1992

Midwest Finishing Systems, Inc. All rights reserved.